Here are some pictures of the watermelons from Erika’s garden. They aren’t the largest melons, but

they are delicious.

On another note, the front

door has been needing a makeover for some time. Over the years, the joints have

shrunk and separated. The door has become impossible to open and close. I took

the door off its hinges and removed all of the hardware. I removed surface rust

from the hinges and painted all of the door hardware a satin black. The black

hardware blends in well with the mission-style motif we are trying to create in

our home…more on that later. The door is solid and heavy. Erika and I carefully

placed the door in the bed of the k-truck. BTW, the truck bed makes an

excellent portable workbench. Unlike the pickup trucks in the states, three of

the sides fold down.

I removed most of the

oxidation from the wood and glued the joints. Pipe clamps were used to hold

everything together. I also added some long stainless steel screws to secure

the joints. The screw heads were concealed with epoxy putty and stained to

match. After the glue cured, I reinstalled the door to determine what needed to

be trimmed and shimmed. The door required about 1/8” of material to be removed

with a skillsaw. Once everything fitted properly, the door was stained to match

the exterior logs. The front door assembly consists of a side window door which

needed to be adjusted and refinished. In all, the project took about two full

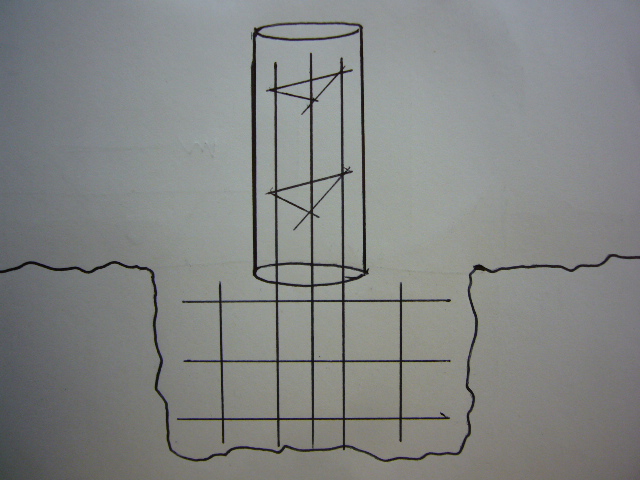

days. At a later time, we will make a stained glass for the window door. I drew

up a design right after we purchased the house. I can’t wait to get that

project started.

On another note, I continued

staining the logs on the front of the house. I preferred to start at the top of

the house and work my way down. Unfortunately, I don’t have the scaffold to

accomplish this. To continue making progress, I decided to start on the bottom

and work my way up. I know this will be a problem at a later time. Power

washing the eaves will make a huge mess on the newly stained logs. Stain and

paint drippings will add to the problems. I’ll have to cover the logs with

tarps and hope for the best.

While staining the lower logs, I encountered some

severe rot on one of the vertical supporting beams. I knew that the rot existed before we purchased the house. I was glad to be finally taking care of it.

The rot had eaten away about a quarter of the diameter of the log. I removed

the rotted areas and was relieved to find that I could shape the area to form a

flat surface. Imagine turning a round log into a square. The flat surface was

treated with an insect and rot preventative and then stained. I’ll have photos

of the completed project in a later post.

I’m into the third year of the remodel and I still have a very long way to

go. George